We’ve had the privilege of working with numerous food startups on their journey to culinary and retail success and we bring great value to our clients by sharing that experience-rich expertise. One of the most critical decisions these budding entrepreneurs often face is selecting the right commercial cooking kettle for their unique needs. Today, we’ll guide you through the essential considerations to help you make the best cooking kettle choice for your startup food production venture.

1. Batch Size and Scalability:

When starting a food production business, you may begin with small batch sizes, but you’ll want a commercial cooking kettle that allows for future growth. Look for a kettle with flexible capacities to accommodate your evolving production demands. Our kettle portfolio offers scalability options to ensure your investment serves your business today and through the early growth stages.

2. Cooking Method:

Commercial cooking kettles come in various types, such as steam jacketed kettles, direct steam kettles, and electric kettles. The choice depends on your specific cooking process and energy source. Steam-jacketed kettles are energy-efficient and suitable for a wide range of recipes, making them a popular choice among startup food producers. Our experienced advisors will match your production and operation needs to the right kettle option and present a comprehensive proposal quickly. To start the matching process, complete our inquiry form. You’ll receive an email reply with the next steps promptly.

3. Temperature Control:

Precision in cooking is paramount for both quality and food safety. Ensure your commercial cooking kettle provides precise temperature control to achieve consistent results. Modern commercial kettles offer advanced temperature monitoring and control systems that help maintain the desired cooking parameters and log data in real-time to ensure compliance adherence.

4. Cooking Time:

Look for kettles that offer rapid heating and cooking capabilities. Our kettle portfolio has been curated with efficiency in mind, reducing cooking times without compromising quality.

5. Material and Build Quality:

The durability of your kettle matters. Stainless steel is a best-practice fabrication choice due to its resistance to corrosion and ease of cleaning. Robust construction ensures your commercial kettle can handle the demands of a busy commercial kitchen.

6. Safety Features:

Safety should never be overlooked. Choose a kettle with built-in safety features like pressure relief valves, lid interlocks, and emergency shut-off systems. These features protect your team and your investment.

7. Ease of Use and Maintenance:

An intuitive interface and easy maintenance are crucial for startup food producers. Look for commercial cooking kettles with user-friendly controls and accessibility for routine cleaning and maintenance tasks. All of the kettles in our equipment portfolio are designed and tested for user convenience and minimal downtime.

8. Versatility:

Versatility can be a game-changer. Consider a commercial kettle that can handle a variety of cooking processes, from simmering to mixing to braising. Flexibility in your equipment can open up new culinary possibilities for your startup.

9. Regulatory Compliance:

Ensure your kettle complies with industry regulations and standards, such as NSF, UL, and HACCP. Compliance is essential for food safety and quality assurance.

10. Technical Support and Service:

Finally, consider the availability of technical support and after-sales service. Having a reliable partner to assist with maintenance and troubleshooting can be invaluable for your startup’s success.

Choosing the right commercial cooking kettle is a critical decision for startup food producers. By considering factors like batch size, cooking method, temperature control, safety features, and more, you can make an informed choice that sets the foundation for your culinary venture. At DC Norris North America, we’re dedicated to helping food startups thrive with our high-quality, versatile kettles and comprehensive support. If you have any questions or need further guidance on selecting the perfect kettle for your needs, reach out.

Here’s to your culinary success!

Explore our Process Kettles featuring equipment brands DC Norris and BCH.

KF/P/IA1 – Fixed Bowl Inclined Agitator

Direct steam kettle designed for the cooking and/or mixing of a wide range of food products, including soups, casseroles, sauces and preserves.

Capacity: 79 – 396 Gallons

Features: Inclined scraping type agitator which has patented scoop-type scraper shovels with replaceable, heat resistant, food approved plastic blades

R2CT/300 – Ready 2 Cook 80 Gallon

Designed to give manufacturers a simple route to food production without compromising quality. The system is ready to start cooking with minimal installation and training required.

Capacity: 80 Gallons

Features: Available in Tilting or Static versions

R2CT/500 – Ready 2 Cook 125 Gallon

Designed to give manufacturers a simple route to food production without compromising quality. The system is ready to start cooking with minimal installation and training required.

Capacity: 125 Gallons

Features: Available in Tilting or Static versions

BCH Orbiter

The BCH Orbiter range is perfect for start-up food manufacturers or industrial food producers who require a smaller batch-size machine. A robust and sturdy construction means our kettle can meet the requirements of the food kitchen environment. All kettles can be used on factory steam or an onboard all-electric self-generating steam package.

Capacity: Up to 132 Gallons

Features:

- Simple operating control interface

- Emergency stop and local mains isolation

- Variable speed agitator with horizontal lift and fold action

- Fitted with food-grade scrapers

BCH Cook Cool

The BCH Cook Cool combines a BCH cooking kettle with a vacuum cooling vessel for a high-performance system. Food can be cooked and cooled quickly, in batch process, reducing labor and energy costs.

Capacity: Up to 792 Gallons

Features:

- Small carbon footprint

- Hygienic operation with CIP system

- Faster product throughput

- Low operating & maintenance costs

BCH Pressure Cook

BCH Pressure Cook can be used for many products including pie fillings, stock-pot style dishes, and vegetables. The BCH Pressure Cook incorporates flexible recipe handling systems, upgraded safety features, and a control philosophy.

Capacity: 2 – 792 Gallons

Features:

- Variable speed scraped surface agitation

- High shear mixing for particle reduction

- Automatic ingredient loading options

- Variable jacket steam pressure control

Batch Vacuum Cooker

The BCH Vacuum Cooker can be used for a wide variety of products including toffee, caramels, jam, competes, and concentrates. A range of process options can be achieved using the kettle including atmospheric and vacuum.

Capacity: Up to 105 Gallons

Features:

-

10-bar steam jacket

-

Hinged manway with safety interlock and inspection port

-

Large bore 75mm diameter manual outlet valve

-

Temperature probe with automatic steam control

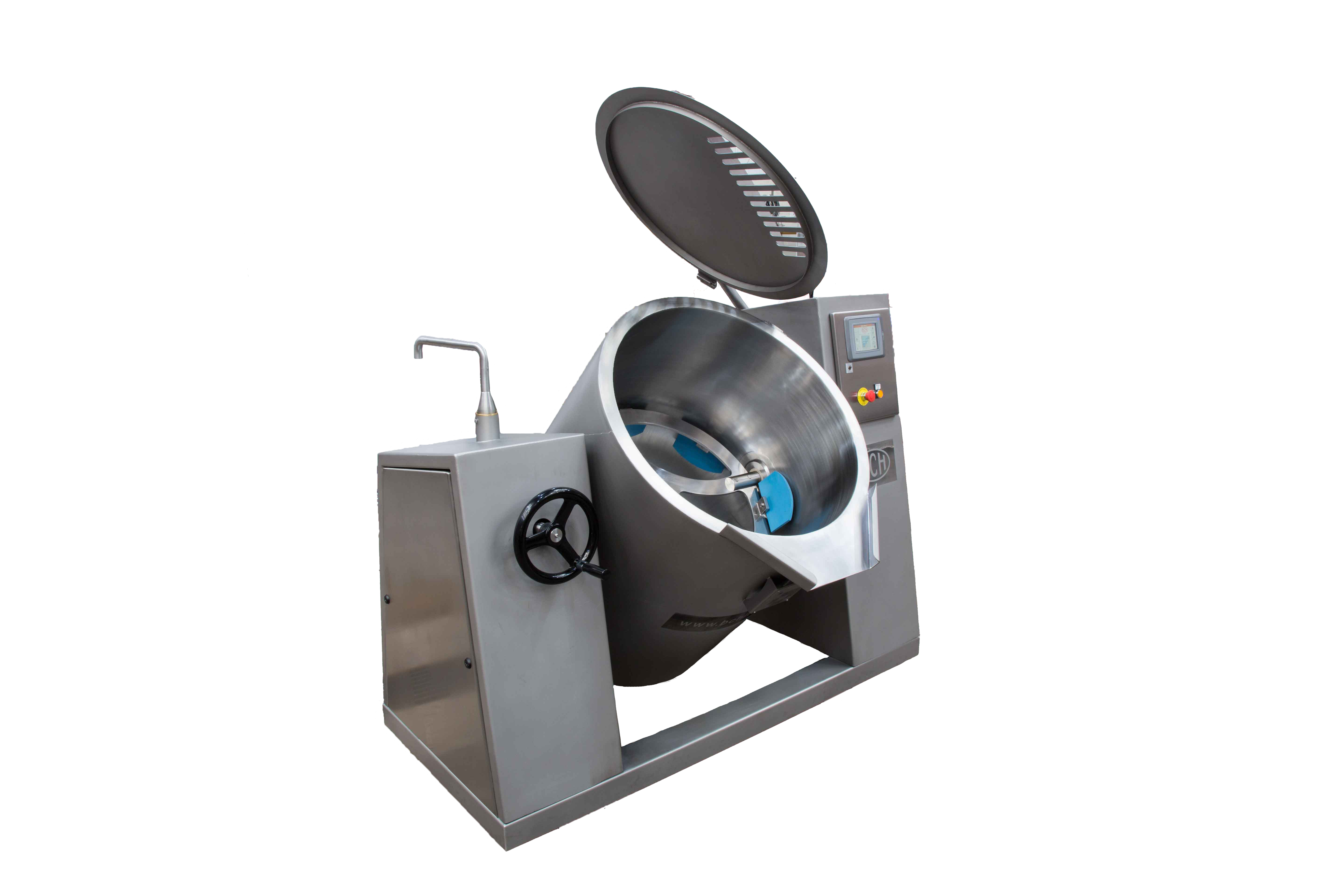

BCH Tilting Kettles

BCH Tilting Kettles offer versatility for a variety of product applications including jam and caramel. Various process options can be achieved using the BCH Tilting Kettles including atmospheric cooking, vacuum cooking and chilling, concentrating, dissolving, and evaporation.

Capacity: Up to 264 Gallons

Features:

- 10-bar steam jacket

- Scraped surface agitator

- Temperature probe with automatic steam control.

- Hinged manway with safety interlock and inspection port.

BCH Cooking & Mixing Kettles

The BCH Cooking & Mixing Kettle range can cover a variety of cooking, mixing, and blending applications across a whole range of products from fish to creams.

Capacity: Up to 1,056 Gallons

Features:

-

Atmospheric, pressure, and vacuum processing options are available.

-

Steam jacket pressure of up to 4 Bar G

-

Fully welded insulation jacket fitted with chlorine-free mineral wool

-

Flange-mounted agitator drive unit with easy access to shaft coupling & mechanical seal

BCH Low Mixer

The BCH low mixers have long been regarded as the industry standard for batch production, many of our customers citing that truly high-quality products can only be made on this machine. Perfect for caramel and fondant production.

Capacity: Up to 132 Gallons

Features:

- Atmospheric, pressure, and vacuum processing options are available

- Steam jacket pressure of up to 10 Bar G

- Tilt out contra-rotating agitator drive unit with easy access for maintenance

- Tilting bowl function

- Flange-mounted agitator drive unit with easy access to shaft coupling & mechanical seal

BCH Optima

The BCH Optima is the ultimate all-in-one system. A range of process possibilities can be achieved with just one machine including confectionery, spreads, dips, soups, and sauces.

Capacity: Up to 132 Gallons

Features:

-

FlexiChef touch screen operator interface to store recipes and view trends

-

Rapid processing ability

-

Equipped with tilting and pump-out options

-

Variable speed-cutting functions (up to 4500rpm)

Process Kettles by DC Norris North America

DC Norris North America offers an extensive range of Steam Jacketed Cooking Kettles built with a traditional high-polished stainless steel finish. These are available in various jacket styles and in a wide range of sizes from 40 gallons to 1320 gallons. Our kettles can reach a very high temperature rapidly with steam pressure of up to 150 PSI.

High Polished Stainless Steel Kettles

Kettles are easy to use and recipes are simple to produce using our recipe management software which provides a straightforward and flexible method of controlling a recipe-driven production process.

Virtual Chart Recorder allows customers to log information relating to temperature changes in any cooking/cooling process, thus enabling them to keep a record of their quality assurance requirements, which can be stored indefinitely.