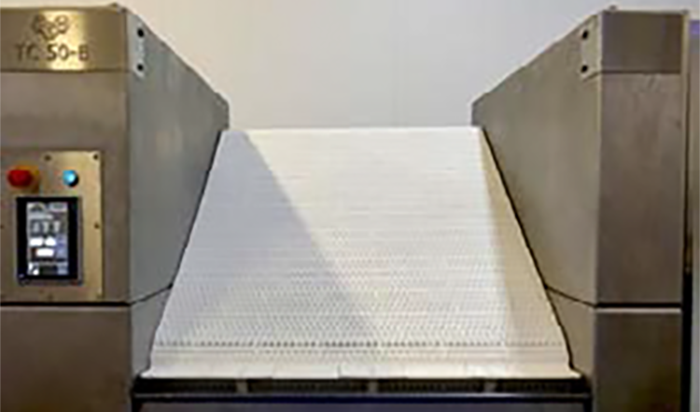

Rotary Tumble Chilling

TC-30 – TC-150

Post-cooking, bagged product is immersed in chilled water, the drum then rotates, gently tumbling the bags and massaging the product to ensure complete cooling and minimal product damage. Large batches of food can be rapidly chilled in their flexible plastic casings to below 4°C (40°F), extending refrigerated shelf life for up to 45 days.

Capacity: 79/132/198/264 Gallons

Features: HMI screen, recycling surge tanks, NSF Certified

BCH RotaChill

The BCH RotaChill is ideal for cooling a variety of products to below 5 degrees C in approximately 90 minutes (product & size dependent). The RotaChill can also be used to extend the product shelf life within the factory environment. The original product will remain fresh without the need to freeze.

Capacity: 396 Gallons

Features:

-

Quick-release filter to prevent blocking of the heat exchanger

-

Automatic rotary bag discharge feature – easy access for bag removal

-

Upper & lower tank inspection and cleaning ports

-

Level control with automatic water top-up

Rotary Tumble Chillers by DC Norris North America

As part of the DC Norris North America cook chill system, filled casings made from a special blend of plastics to retard bacterial growth are conveyed into a purpose-built rotary tumble chiller. This method reduces the temperature of cooked food to below 40°F (4°C) in under an hour, with cooling times and temperatures fully logged. Sealed casings are then placed in chilled storage at below 40°F (4°C) and can be stored for up to 45 days.

When the product is required for final processing, casings are opened and product is filled in the conventional way or deposited into the chosen packaging. If the product is destined for immediate consumption, in a restaurant or hospital for example, then it can be reheated and served, and will retain the quality and taste of a just-cooked meal.

Request a Future Appointment

Are Rotary Tumble Chillers Right for Your Product Line?

- Available in 80, 130, 200, and 250-gallon capacities

- All stainless steel design

- Microprocessor control

- Large or small batch sizes

- Easy to use HMI

- E-terminal data logging (optional)

- Cleaning cycle

- Surge tank for water recovery (optional)