Supercharge Your Process Kettles with Jet Cook

Download the Jet Cook™ Spec Sheet

Jet Cook™ Can be Purpose-Built or Retrofitted to Any Steam Jacketed Kettle 80 Gallons or Larger

Jet Cook™ Technology delivers fast, flexible, and efficient liquid food, beverage, and wet pet food processing solutions, utilizing high-performance steam technology.

The system offers significantly reduced processing times and dramatically cuts clean-in-place requirements, without

compromising quality or flavor. Jet Cook™ is a revolutionary fluid processing solution that can homogenize, emulsify, entrain, pump, and heat with impressive performance.

- Reduce Cooking & Processing Times

- Reduce Energy Use

- Improved Product Quality & Particulate Integrity

- Reduced Processing Stages

- Reduction in Ingredient Quantities

- Eliminate or Reduce Burn On

- Increased Throughputs

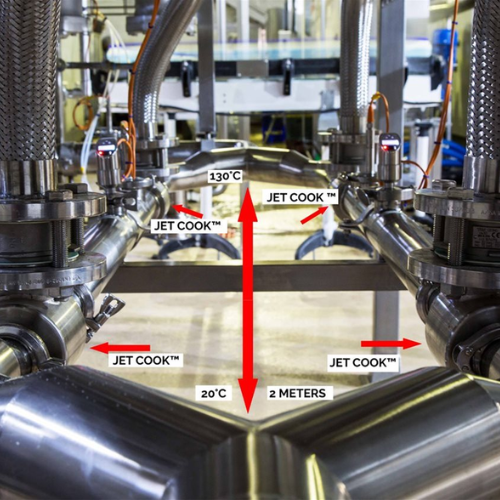

The Science Behind Jet Cook™:

Steam is accelerated and atomized, creating 7 trillion droplets of water a second at high pressure directly into the product through DC Norris’s patented steam conditioning chamber and annular nozzle arrangement. As the steam collapses it creates a partial vacuum and pulls the product through the system back into the vessel while simultaneously heating, mixing and pumping. Manufacturers can benefit from rapid heating and huge energy savings as 99.5% of the energy is collapsed directly into the product. Scientific trials have shown that 52.5% less energy was used when cooking with Jet Cook™ compared to cooking the same product in conventional kettles. Calibrated steam flow meters were used to measure the flow and capture the data.

Jet Cook™ Features

Jet Cook™ Case Studies

Jet Cook shows remarkable time and energy savings in the preparation of bechamel sauce, both liquid-milk-based and powder-based (flour, SMP, starch, mustard powder). In recipe trials, the batch time was reduced from two hours using an electric kettle to under 30 minutes using Jet Cook. The finished bechamel also had improved texture, creaminess, and yield using Jet Cook because of its remarkable ability to hydrate the starch and flour.

Producing Oat Milk is traditionally a multi-stage operation involving pre-soaking oats, heating, homogenization, amylase addition, and a hold stage. This is then followed by final heating to ensure the complete denature of the amylase before cooling and filling.

Using steam-jacketed kettles or heat exchangers for this process results in a thick viscose mixture that can burn. The burning causes an undesirable malted caramel-type flavor or a bitter burnt oat flavor.

Using our Jet Cook system, we’re able to heat and homogenize all of the oat milk ingredients in one tank to 185°F in approximately 4 minutes. The finished product has a naturally sweet and oaty flavor with a creamy/smooth mouthfeel required of barista-style oat milk.

The high shear function of the In-Tank Jet Cook converts the un-soaked oats into a more desirable product much quicker than traditional methods. The natural sugars are released due to the simultaneous activation of the amylase and denaturing it extremely quickly without an additional heating stage. The process of moving water into the oats so that they can release their starch is dramatically expedited using Jet Cook allowing them to swell and become soft without the undesirable taste changes that occur through long and extreme heating conditions.

Chocolate ganache, used to coat and enrobe desserts, can prove challenging to produce as overheating causes sugar blooming, separation, dull finish, and a grainy texture.

Using our Jet Cook system, the butter is easily melted without burning/catching. The cream is quickly heated without any burning onto the side of the vessel, followed by the addition of chocolate which is mixed quickly and evenly to avoid separation.

By using a low-pressure jacket, in-vessel homogenizer, and an inclined folding agitator with patented scoops/blades we’re able to achieve 440lbs of perfect chocolate ganache in less than 20 minutes.

Bring In The Best™

The processing equipment manufactured and sold by DC Norris North America sets the standard in the global food production industry. So too, do our teams. With more than half a century of global food processing expertise at our fingertips, we empower North America’s most-loved food brands to continually redefine our food culture.

Together, we innovate to design systems and equipment that produce foods that set new standards in convenience, safety, and accessibility by improving manufacturing efficiency and minimizing environmental impact. When North American food brands have processing challenges to solve, they count on DC Norris North America to Bring In The Best™.