Equipment Focus: The CQC Adapt

With 30 years of cook chill equipment manufacturing and innovation under its belt, DC Norris launched the CQC Adapt in 2021 to bring versatility, resource conservation, and improved speed to the company’s cook chill equipment portfolio.

Meet the CQC Adapt

The CQC (Cook Quench Chill) Adapt is a versatile, intuitive machine designed to meet the rigorous demands of the industrial food production industry. An ideal fit for the cooking of rice, pasta, potatoes, and vegetables, the CQC Adapt cooks or blanches products continuously at faster speeds than previous cook quench chill systems thanks to the addition of two patented Jet Heat direct steam heat systems.

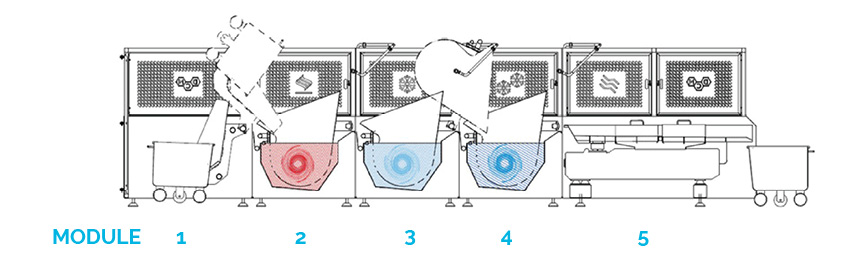

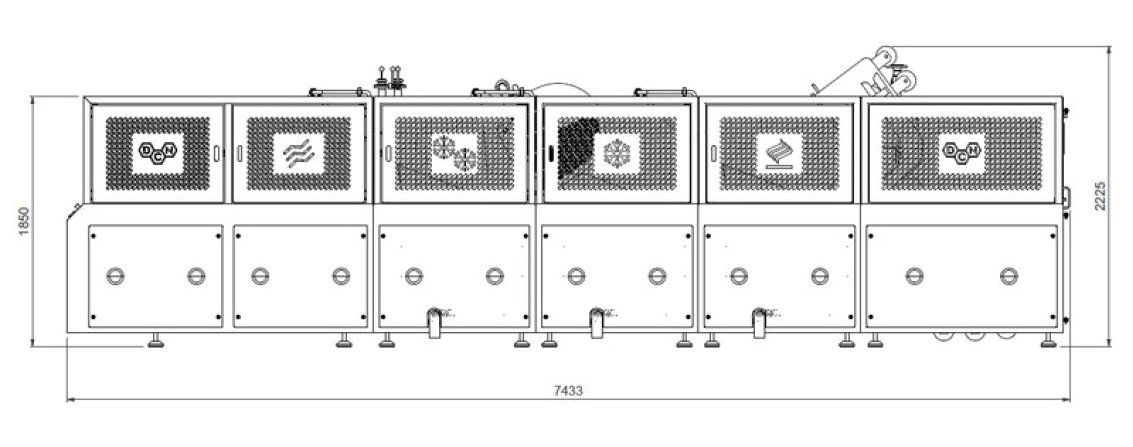

The standard CQC is made up of three main parts, ‘Cook’, ‘Quench’, and ‘Chill’. The versatility of the ‘Adapt’ series means that modules can be added or removed according to throughput.

Standout Features of the CQC Adapt

The CQC Adapt is the culmination of a variety of features designed to speed up the production process while maximizing resource efficiency, ensuring product quality, and being flexible to batch requirements.

Starch Removal System

All 3 tanks (cook quench chill) have a separate weir to allow the starch to be run off during each change, reducing the need for frequent water changes.

Variable Wave Agitation System

The CQC Adapt is fit with variable wave agitation which pumps hot water from the cook tank through to the wave nozzles positioned at the rear of the cooking basket. The speed of agitation can be controlled through the recipe control software package, ensuring finished product integrity and quality.

See the variable wave agitation system at work here:

Full Automation

The CQC Adapt is available with the option of DC Norris’ Process Management System and data capture software offering fully automatic cook, quench, and chill processes including draining discharge, and CIP.

See how 100% of the product is removed during discharge here:

Flexible Capacity

Food manufacturers get remarkable flexibility thanks to the modular construction of the CQC Adapt. The CQC Adapt can be installed over a high care/low-risk barrier, or it can be implemented as a single unit with the opportunity for expansion at any time to give a larger capacity and throughput. The modular Installation is simplified with the modules attaching easily together before connecting to services

Maximized Water Savings

The CQC Adapt features smaller tank capacities and variable water levels that can be adjusted to suit different batch requirements. Additionally, internal heat exchangers offer continuous chilling and precise control of the quench and chill water temperature. The exchangers help manufacturers save water with recirculation. The stainless steel heat exchangers are cleaned as part of the CIP process. Backflushing is also available.

Patented Jet Heating Speeds Production & Cleaning

The Jet Heat nozzles collapse steam into the product at high velocity. As the steam collapses it pulls the product (liquid) through, creating a recirculating effect (partial vacuum) in the re-circulating pipe. 99.5% of the steam is utilized and then collapsed into the product ensuring huge energy savings. Jet Heat replaces heat exchangers which can scale and impact heat up times. The heating system is fitted with a sterile steam filter arrangement and hygienic EHEDGE and AAA-approved pumps.

See the Jet Heat system at work here:

Unique CIP Efficiency

The CQC Adapt pipework can be cleaned in place using water heated by the in-tank Jet Cook system. Through the programmable CIP, sterilizers and cleaners are added to each basket. Integral spray balls wash out each of the three baskets.

The CQC Adapt Modules

Module 1: Product loading

Hydraulic Euro Bin tipping unit integrates into the CQC Adapt at the cook position. It can be lowered to operator level for product loading, and raised for loading into baskets.

Module 2 – Cook

The product is cooked quickly and evenly using Jet Cook™ technology, achieving 100% energy into the water. The variable flow wave agitation system ensures even cooking and removes clumping issues.

Module 3 – Quench

The Quench vessel is loaded with cold water to stop the cooking process and to rinse/wash the product before the chilling phase.

Module 4 – Chill

Rapidly reduces the product temperature to below 37 °F. The chill vessel is initially filled with cold water from the mains and the temperature is lowered by circulating through a heat exchanger.

Module 5 – Unloading

The CQC Adapt utilizes a vibratory de-watering conveyor. The stainless steel trough vibrating conveyor drains water from the product before discharging into a standard tote bin or product trays.

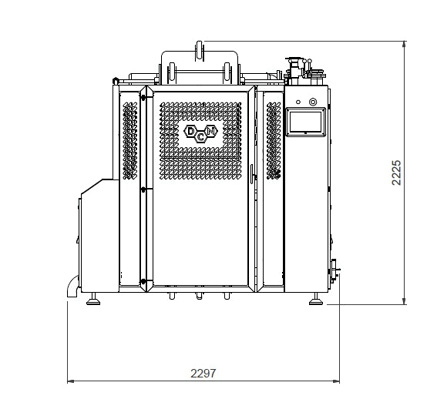

CQC Adapt Service Requirements

- STEAM: 800kg/hr @7 barg •

- AIR: 6 barg .3 m3 /hr

- POWER: 100 amps per phase

- WATER (MAINS): 525 l/min @2 barg

- GLYCOL CHILLER: 3 barg 400l/min 0°C Maximum cooling duty – 150kW

See How CQC Adapt Works

- https://www.youtube.com/watch?v=pbspeqKs61I

- https://www.youtube.com/watch?v=Ko_DXyFtP28

- https://www.youtube.com/watch?v=6KxOsjVwP9s

- https://www.youtube.com/watch?v=n77u3R-frRU

- https://www.youtube.com/watch?v=4cLkS5Oyta8