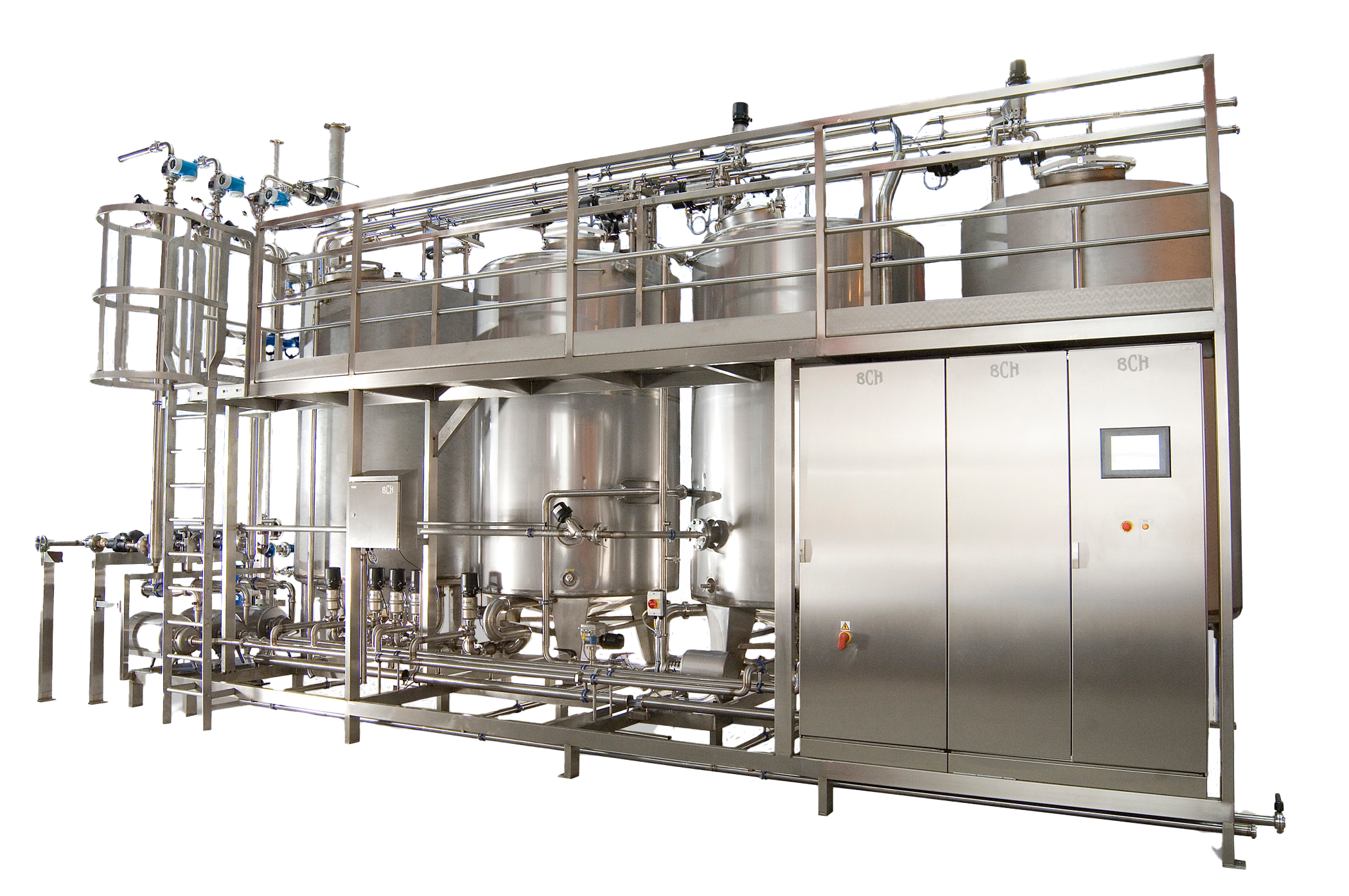

Clean in Place

CIP systems are built and tailored to meet the specific process application requirements. Our clean-in-place solutions encompass everything from simple once-through total loss rinse systems to fully automated multi-channel recovery systems.

With extensive experience in building CIP systems for the ready meal market, we’re well equipped to build a CIP system that consists of several rinsing cycles where the cleaning material is circulated through the pipework, valves, pumps, cooking equipment, and holding vessel.

Integrated CIP systems create efficiencies by increasing available line production time and reducing required cleaning materials.

Commonly, our CIP systems are custom designed and manufactured as a fully

assembled and pre-wired modular skid package.

Features include:

- Stainless steel construction

- Sanitary design principles

- Up to 1,585-gallon capacity feed and recovery tanks

- Fully automated sequencing of the cleaning process along with complete integration with the core food process

- HMI controls with stand-alone PLC connected to the main process plant via ethernet

- Configurable cleaning recipes via the HMI

- Automatic detergent dosing, with full monitoring of outgoing and incoming detergent strength (pH conductivity probes)

- Multi-channel options, each with variable speed delivery pump control

- Automatic monitoring of water flowrate and temperature on the flow return feed of each individual channel provided

- On-board steam heated heat exchanger systems complete with modulated steam control

- Optional waste product recovery tank